Developed the first large-size, fully automatic AlN PVT sublimation reactor in China.

In order to grow large-size AlN single crystals, countries around the world have made long-term unremitting efforts in crystal growing methods and processes in the past 50 years, but the progress is very slow. The physical vapor transport (PVT) is recognized as the only method for growing large bulk AlN single crystals, and this method is also an approach for growing large-size bulk SiC single crystals. The fundamental research on the growth of AlN and SiC single crystals both started in the 1970s, but tremendous progress on the SiC single crystals has been achieved. At present, 8-inch (200mm) diameter SiC wafers are being in mass production by leading companies. Nevertheless, research institutions and enterprises worldwide capable of growing 1-inch (25.4 mm) diameter AlN single crystals are extremely limited nowadays. Huge challenges are posed to the hot zone design, control system and equipment for the AlN single crystal growth due to the high growth temperature and stringent growth conditions. Therefore, The AlN single crystal and AlN single crystal growing equipment have been listed as key strategy material and equipment in “Made in China 2025” unveiled by the State Council and the Ministry of Industry and Information Technology (MIIT) of the People's Republic of China.

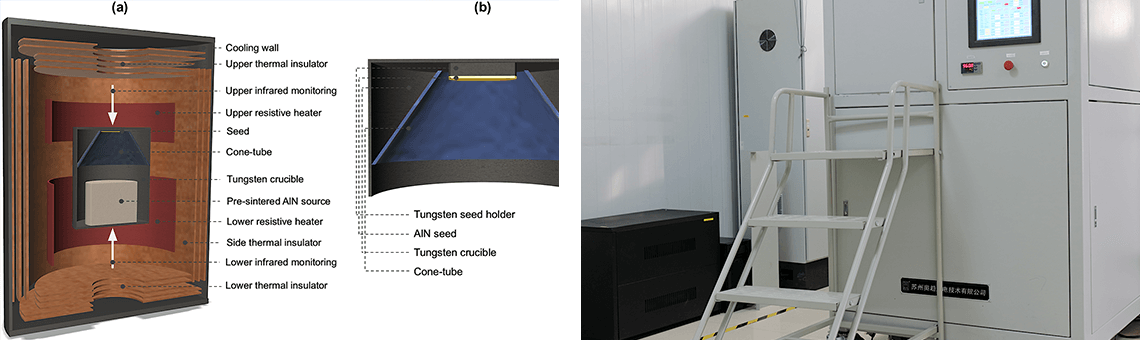

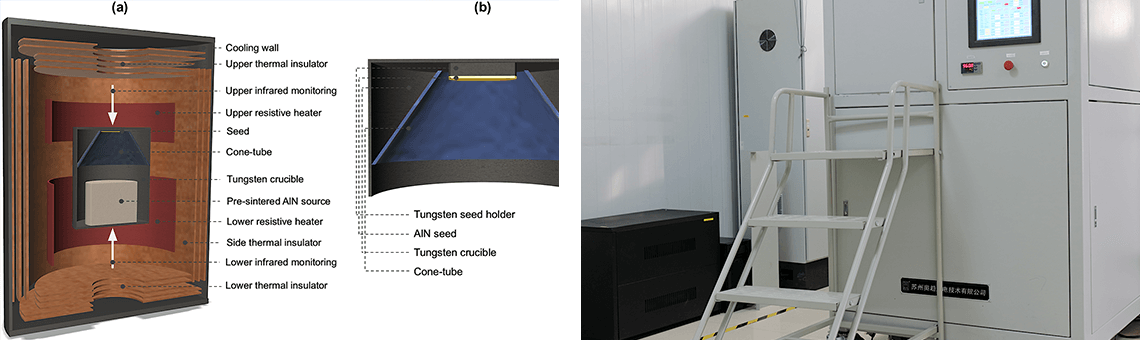

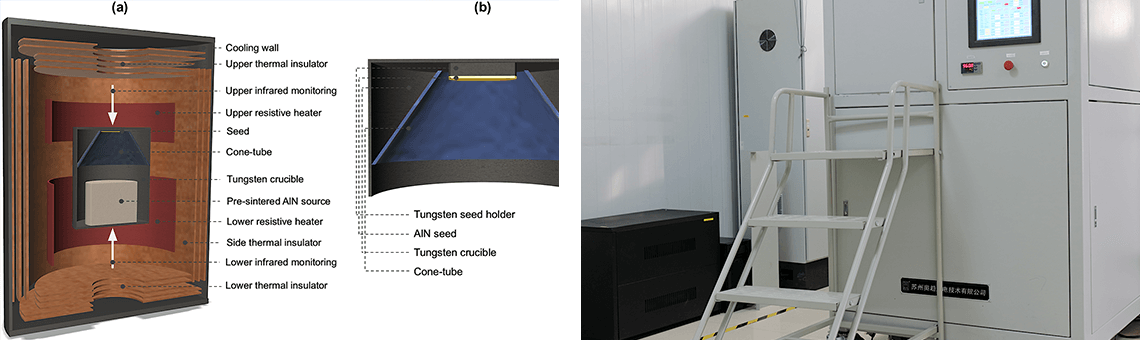

Through proprietary design and overcoming various difficulties, the R&D team of Ultratrend Technologies Co., Ltd. has successfully developed the Generation-I and the Generation-II fully automatic AlN PVT sublimation reactors with complete intellectual property rights respectively. Ultratrend Technologies Inc. Generation-II AlN PVT sublimation reactor is a fully automatic (almost no manual intervention) and first high-end equipment in China that has 4-inch AlN single crystal growing capability for industrial mass production. Based on this equipment, Ultratrend Technologies Co., Ltd. successfully developed the world-first Φ 60mm high-quality AlN single crystals with world-leading ultraviolet transparency in November 2018. This significant progress made by Ultratrend Technologies Co., Ltd. has laid a solid foundation for the large-scale industrial application of AlN single crystalline substrate worldwide.

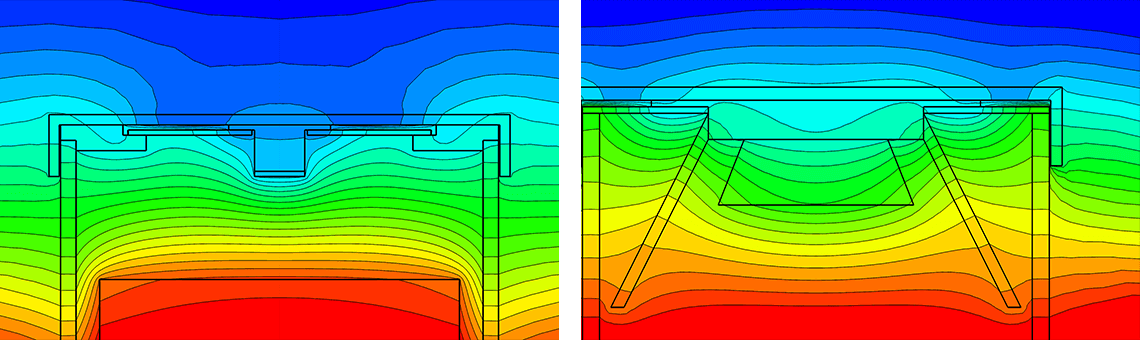

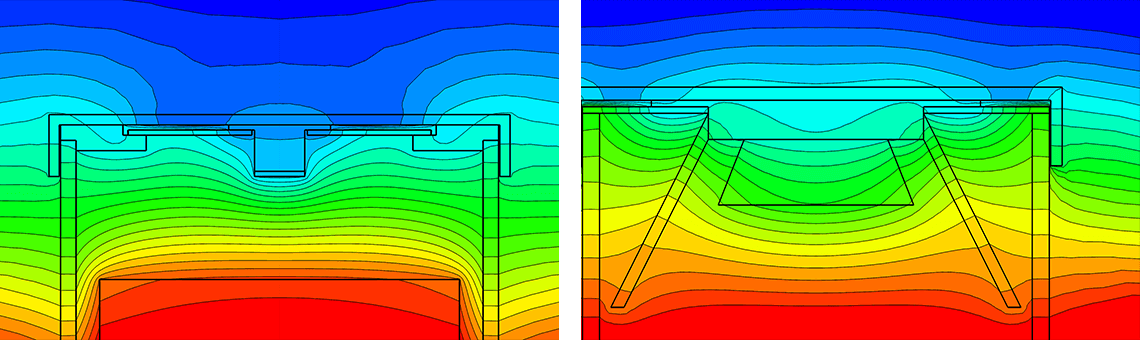

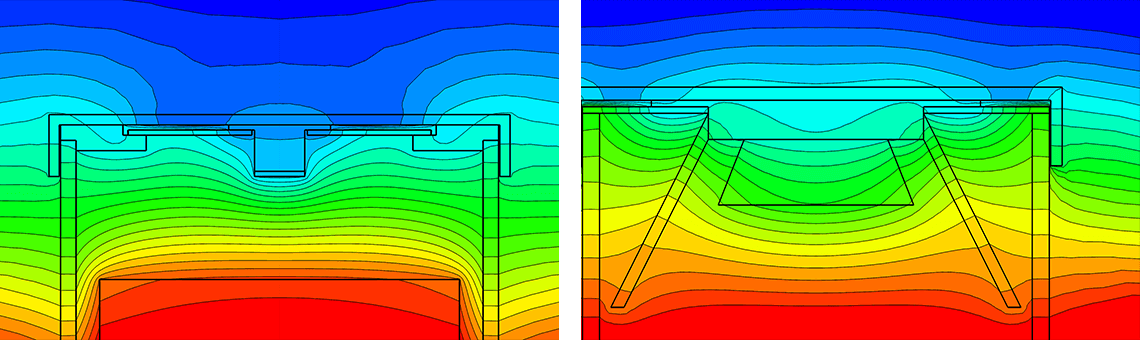

Ultratrend Technologies Co., Ltd. Generation-II AIN PVT sublimation reactor, featuring a dual-tungsten resistance heating, has two resistive heaters which are independently controlled by advanced computer control technology to allow flexible and precise adjustment of the temperature field in the reactor. The insulation materials for the thermal field are high-purity tungsten metal with high-temperature resistance and low surface emissivity. As a result, volatiles in the reactor are few, and AIN single crystals can be grown with low impurities and dislocation density. The reactor mainly comprises a vacuum reactor chamber, a heating insulation system, a power supply and control system, and a water cooling system. Ultratrend Technologies Co., Ltd. has made innovative breakthroughs in the Generation-II UTI-PVT-D075H single crystalline reactor and associated technologies for AlN single crystal growth and obtained nearly 30 patents. It has thus become the only hi-tech, innovative enterprise in the world that can provide AlN turn-key solutions and professional technical services to its customers, arranged from the growth reactor and hot zone design, modeling and simulation, process optimization, and wafering process.