Ultraviolet LED - The Eve of Market Outbreak

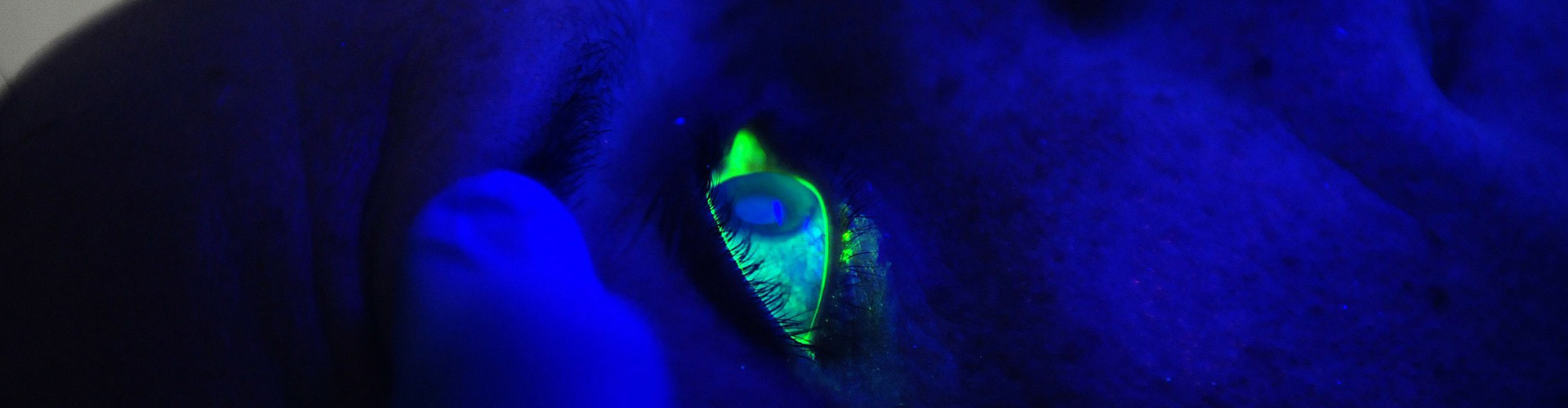

According to the Minamata Convention on Mercury, 128 contracting parties worldwide will completely ban the use of traditional ultraviolet mercury lamps by 2020. UVC-LED based on AlN substrate is currently the best solid-state light source solution to replace mercury excited ultraviolet light source. Its advantages include (1) high efficiency: physical sterilization, and light intensity per unit area exceeding 1,000 times of mercury lamp; (2) environmental protection: AlN material is non-toxic and harmless, and ultraviolet LED and its packaging process do not contain any toxic substances; (3) energy-saving: with low pressure, no preheating time, no heat radiation, the power consumption is only 10% of that of mercury lamp under the same output power, and the maintenance cost is almost 0; (4) reliability: the service life is more than 20,000 hours, which is 10 times that of traditional mercury lamps, and the service life is almost not affected by the number of switches.

According to the forecast of industrial insiders, the global potential market size in the field of sterilization and disinfection of deep ultraviolet LED alone will exceed USD 500 billion, and the deep ultraviolet LED is widely used in biomedical, drug research and development, anti-counterfeit identification, air purification, high-density storage, ultraviolet laser, military (ultraviolet detection, ultraviolet secure communication) and other fields. According to the consulting firm Yole Development, the compound growth of the UV-LED market exceeded 43% from 2012 to 2018 and the market size will grow 100-250 times in the next 5 years.

Therefore, the ultraviolet LED market has become the next "new blue sea" market. This market is currently on the eve of an outbreak, and the bottleneck of the outbreak strongly relies upon the supply of the AlN substrates. At present, only two enterprises worldwide can manufacture 1-2 inch AlN substrate with very limited volume and extremely expensive selling price. There is a huge contradiction between the huge demand and supply of AlN substrates due to the technology barrier and high manufacturing/procurement cost.

Ultratrend Technologies Co., Ltd. has developed a serial of proprietary and patented technologies and state-of-the-art facilities to massively fabricate different sizes of high-quality AlN substrates ideally suited for optoelectronics, including deep UV-LED devices. Accordingly, Ultratrend Technologies Co., Ltd. has become a world-leading substrate supplier and turn-key solution provider to promote the market outbreak.

5G Communication - A New Generation of Basic Productivity

5G is a new generation of basic productivity that opens a new era of industrial digitalization and the Internet of Things. Countries around the world regard seizing the highest point of 5G communication technology as an important strategy for their national development. They have begun to actively determine development strategy not only on network deployment but also on the aspects of key materials, devices, and components.

Compared with traditional 4G and other communication technologies, the working devices of 5G communication technology need to meet three basic requirements, such as full-spectrum access, high-frequency band and even millimeter-wave transmission, and ultra-high broadband transmission. Therefore, large-scale integration, high frequency and high spectrum efficiency also need to be realized for materials such as device, antenna, light transmission and packaging. The packaging template is an important component material of chip packaging. AlN templates are ideal materials for 5G RFFE (RF front-end) chips due to its characteristics of low dielectric loss, high chemical stability, high corrosion resistance, good airtightness, high thermal conductivity and matching thermal expansion coefficient.

Because the radio frequency front-end module (FEM) will need to process a larger number of high-frequency 5G signals, the demand for high-frequency filter will see explosive growth to suppress external interference and provide better communication experience. The key to the preparation of high-frequency filter lies in the piezoelectric characteristics of the materials. AlN templates have become ideal materials for 5G high-frequency filter due to their good piezoelectric characteristics and high sound velocity.

Therefore, with the advent of the 5G era, AlN materials will also unveil their new application with a broad development prospect and huge potential.

MEMS sensor - the basic technology of IoT

According to MEMS Consulting, the MEMS sensors market will achieve significant growth between 2019 and 2024: in terms of market revenue, the CAGR reaches about 8.3%, and it is expected to generate over $18.5 billion in market revenue in 2024, and meanwhile, the CAGR of sales volume will reach about 11.9%.

MEMS sensors are widely used in communication/mobile devices, smartphones, wearable/implantable devices, medical devices, etc. In the IoT era, communication technology only provides IP address assignments and networking. The construction of application scenarios, the interaction between smart devices and application scenarios must be achieved through sensors. Therefore, sensors are the basic technology for building the interconnection of everything in the IoT scenarios.

The combination of piezoelectric properties of AlN and MEMS technologies will open up a wide range of new applications for AlN materials. Dr. Udo-Martin Gomez, Senior Vice President of Bosch Sensortec (world-leading automotive and consumer electronics MEMS sensors manufacturer), said that AlN is the preferred material in piezoelectric sensing applications, in addition to CMOS compatibility and ease of integration, AlN's main advantages are low dielectric constant and dielectric loss, and AlN based MEMS can achieve high-resolution ultrasound imaging on small devices.